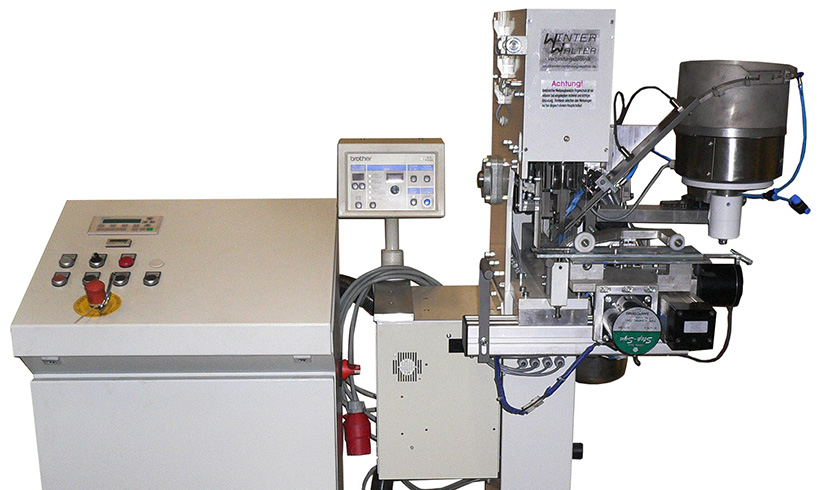

Machine type 1012

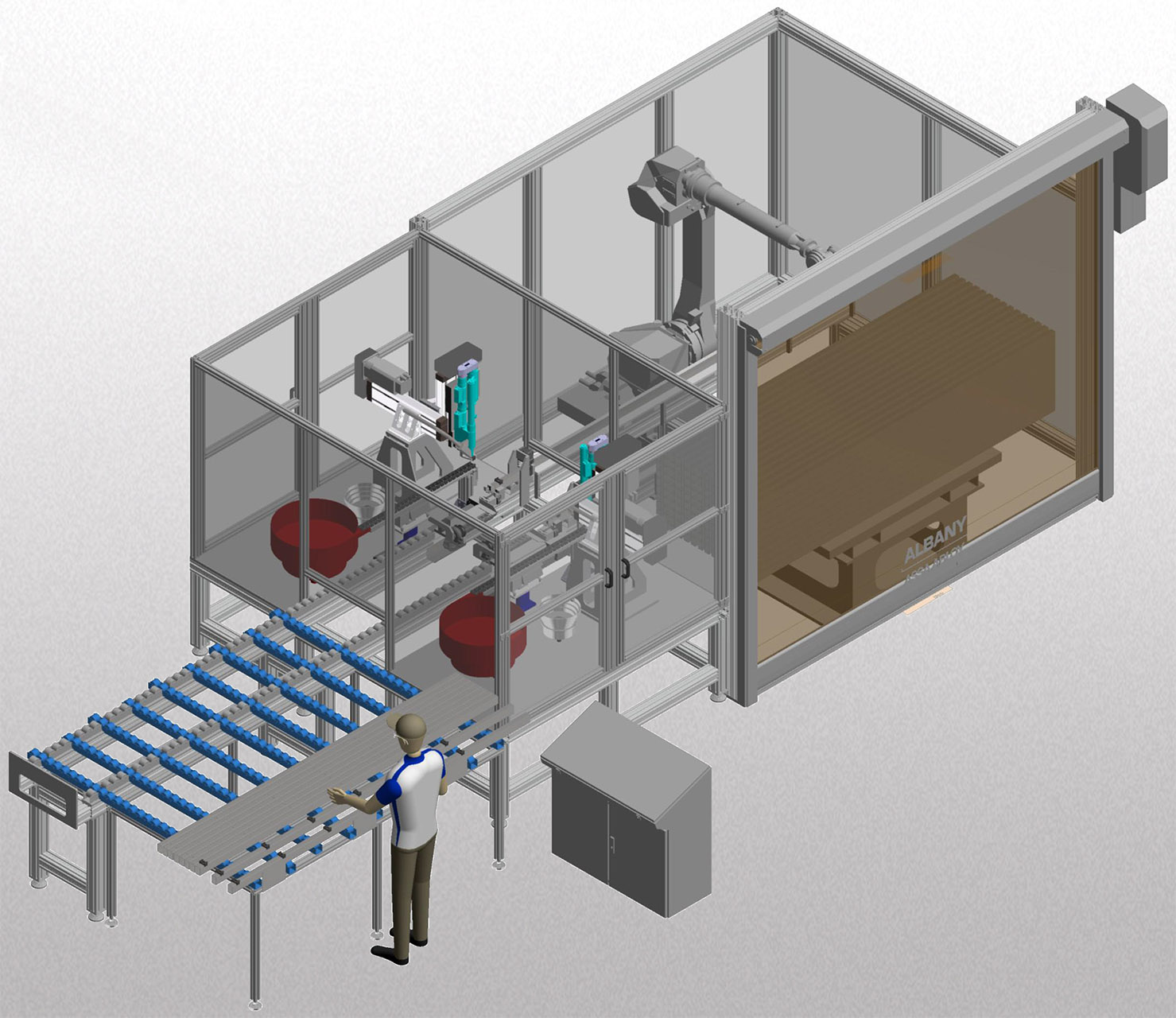

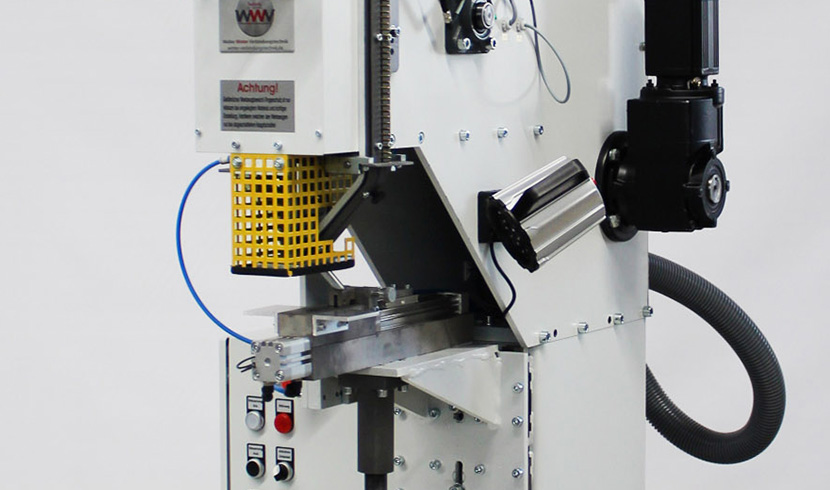

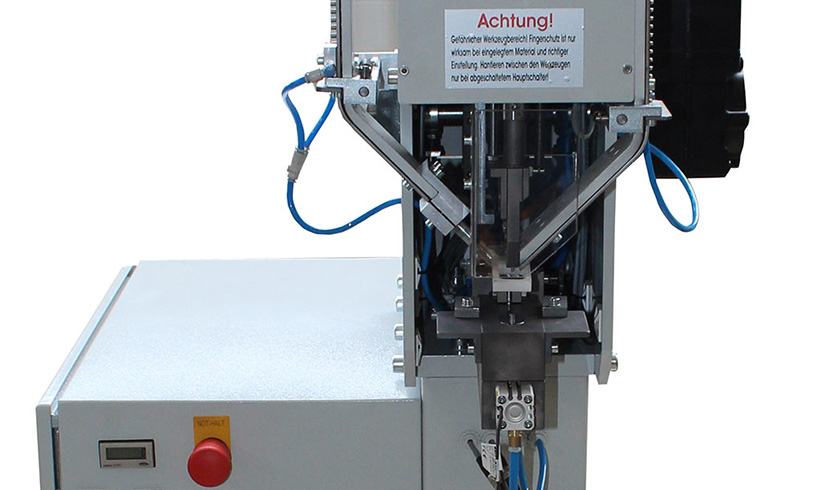

Magnetic adhesive station for luxury packaging

Magnetic adhesive station for luxury packaging for inserting magnetic or steel discs into cardboard. The cardboard is stacked in an insertion device and removed automatically. Two blind holes are milled simultaneously, the chips are extracted, and glue is then applied. The magnetic or steel discs are separated by a feeding system and inserted into the blind holes. The finished cardboard is removed via an ejection portal and placed on a conveyor belt for further processing. Simple adjustment for format changes is easily possible. With protective housing, automatic feed, and piece counter.

Technical specifications

- Control cabinet with PLC control and control panel

- Cardboard feed: Stack magazine

- Magnet feed: Feeding system with separation

- Glue application: Gluing station via nozzle system

- Output: 225 cycles/hour with 4 magnets

- Drive: Electro-pneumatic

- Working height: approx. 1100 mm

- Weight: 2000 kg

- Space requirement: 4100 x 4100 x 2000 mm

- Air pressure: approx. 6-8 bar

- Min. cardboard format range (width x height x thickness): min. 260 x 145 x 2 mm

- Max. cardboard format range (width x height x thickness): min. 1400 x 730 x 4 mm

- Magnet, steel disc thickness: 1.5, 2.0, 2.5 mm

- Magnet, steel disc diameter: 10, 12, 15 mm

Examples of use

- Packaging industry

- Paper industry

- Luxury packaging

- Office supplies

- etc.

Usage videos

Magnetic adhesive machine type 1012

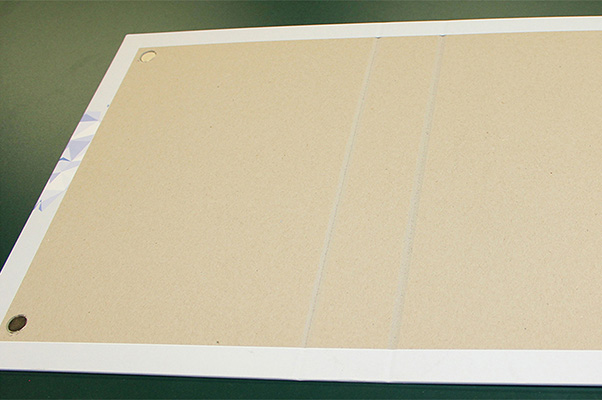

Sample images luxury packaging

Other special-purpose machines

Machine type 1012

Magnetic gluing station for luxury packaging for inserting magnetic or steel disks into cardboard. The cardboard is stacked in an insertion device and automatically removed. Two blind holes are milled simultaneously, the chips are…

Machine type 1011

Assembly system for plastic clamp holders in fence posts for automatic processing. The plastic clamp holders are fed automatically via a vibratory conveyor with linear system and placed on the fence posts.

Machine type 1005

Electro-pneumatic double-setting machine for floor mat fasteners for automatic insertion into textile mats. The upper and lower plastic parts are each fed and pressed in automatically via a vibratory conveyor and conveyor belt.

Machine type 1002

Hydro-pneumatic punching press for round and oval holes in coils or endless strips. The endless strips are automatically calibrated before punching. The coil strips are guided through the system. Programmable punching position.

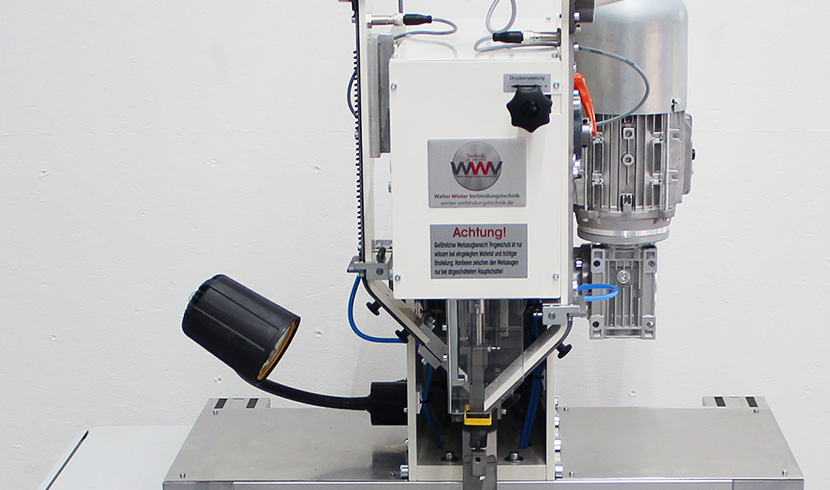

Machine type 090-20

Pneumatic press stud machine with ball part feed for automatic insertion. The ball parts are fed automatically and positioned by a steel strip pusher. The upper parts of the press studs are also automatically…

Machine type 080-30

Electric horizontal double riveting machine for plastic carrier belts on detergent containers for automatic insertion of self-piercing rivets. The rivets are automatically inserted via a driven sorting drum on the left and right…

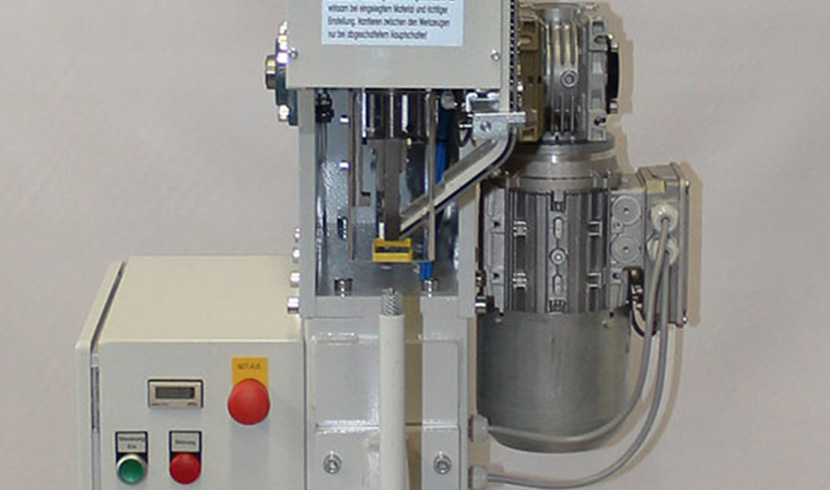

Machine type 060-16 (2)

Electric riveting machine in special design for rivet pins for automatic insertion into pre-punched material. The rivet pins are fed automatically via a vibration conveyor and are positioned and held in place by a pusher.

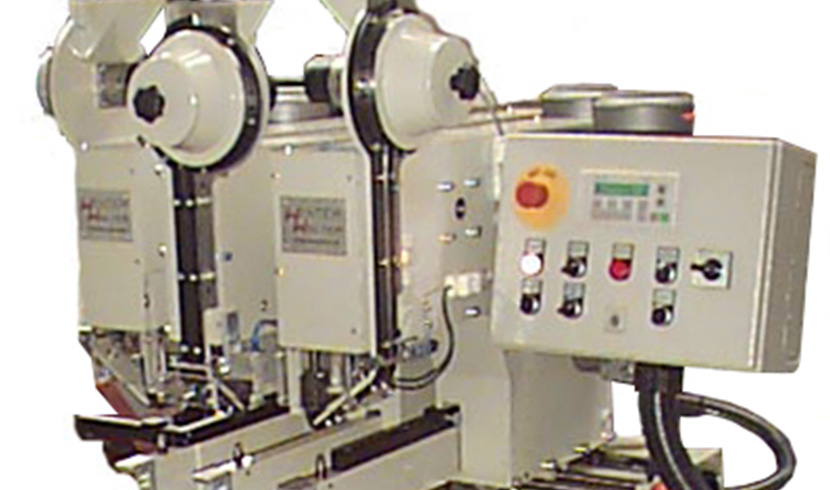

Machine type 1007

Freely programmable 4-fold automatic belt riveter for the automatic insertion of four different self-piercing rivets in a single operation. The rivets are automatically fed and pressed in via a vibration conveyor.

Machine type 090-01 (4)

Electric riveting machine with bottom part feed, bottom punch movement and hold-down device for the automatic insertion of 2-part hollow rivets of various lengths into pre-punched material. The rivet bottoms are automatically…

Machine type 090-01 (3)

Electric riveting machine with bottom part feed and bottom punch movement for the automatic insertion of 2-part hollow rivets of various lengths into pre-punched material. The rivet bottoms are fed in automatically and are…

Machine type 090-01 (2)

Electric press stud machine with bottom part feed for automatic insertion. The press stud bases are fed in automatically and positioned and held in place by a steel strip pusher. The press studs are…

Machine type 090-01

Electric riveting machine with bottom part feed for automatic insertion of 2-part hollow rivets into pre-punched material. The rivet bottoms are fed automatically and positioned and held in place by a steel strip pusher.

Machine type 080-10

Electric 3-fold riveting machine for the automatic insertion of rivets in ring binder mechanisms. The rivets are automatically fed and pressed in via a driven sorting drum on the left, right and front.

Machine type 080-05

Electric 2-fold riveting machine for the automatic insertion of rivets into pre-punched material. The rivets are automatically fed and pressed in via a driven sorting drum on the left and right.

Machine type 065-20-2

Freely programmable 2-fold automatic belt riveter for the automatic insertion of two different self-piercing rivets in a single operation. The rivets are automatically fed and pressed in via a vibration conveyor.

Machine type 060-16-200V

Electric riveting machine in reinforced design for the automatic insertion of drilled rivets up to 55 mm in length into pre-punched material. The rivets are automatically fed and pressed in via a vibration conveyor.

Machine type 065-20

Freely programmable automatic belt riveter for the automatic insertion of self-piercing rivets. The rivets are automatically fed and pressed in via a vibration conveyor. Equipped with a quick-change device for the…

Machine type 060-16-420

Electric riveting machine with horn anvil for the automatic insertion of rivets into pre-punched material. The rivets are automatically fed and pressed in via a driven sorting drum. The pressure can be adjusted depending on the material thickness.

Machine type 060-16

Electric riveting machine for the automatic insertion of self-piercing rivets. The rivets are automatically fed and pressed in via a driven sorting drum. The pressure of the rivets is adjusted via a…