Walter Winter Verbindungstechnik

We offer high-quality riveting machines, eyelet machines, presses, packaging machines, and special-purpose machines. As an experienced manufacturer, we develop innovative solutions for your individual requirements.

Our slogan, “Technology that connects”, sums it up perfectly: We are a medium-sized mechanical engineering company dedicated to connection technology. We offer our customers a wide range of riveting machines, eyelet machines, presses, and packaging machines. If you need something very specific, we develop customized special machines that meet all your requirements.

In short: we manufacture “technology that connects.” We are based in the heart of the “Ländle,” in vibrant Baden-Württemberg, the state of inventors and thinkers. Right where INNOVATION is written in capital letters. In Göppingen (Voralb region), at the gates of Hohenstaufen.

Our offer

Discover our comprehensive range of joining technology machines – the right automation for every application.

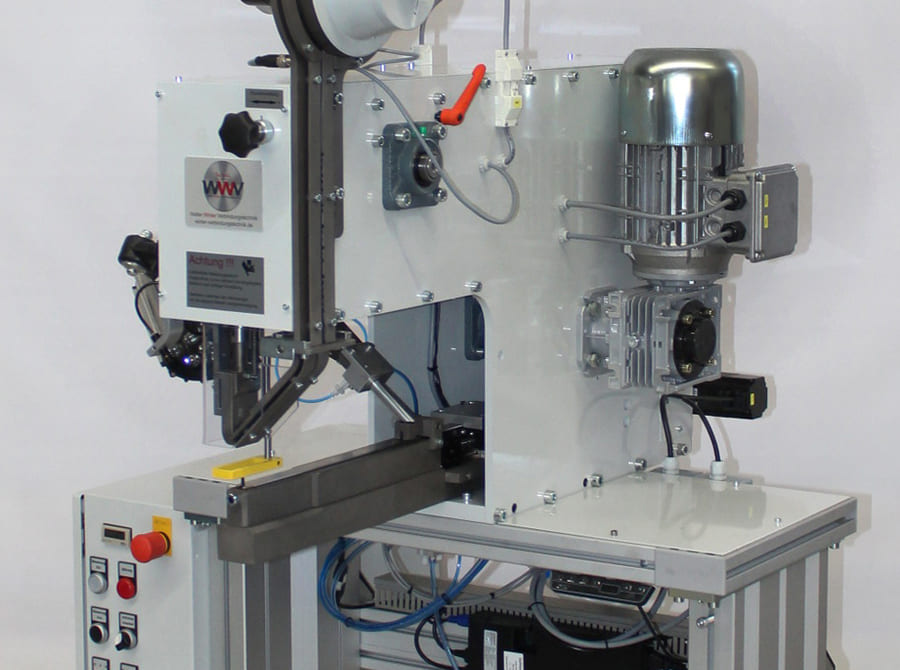

Riveting machines

With modern technical concepts and robust construction, our riveting machines guarantee high reliability and quality. All our riveting machines are developed and produced entirely in-house.

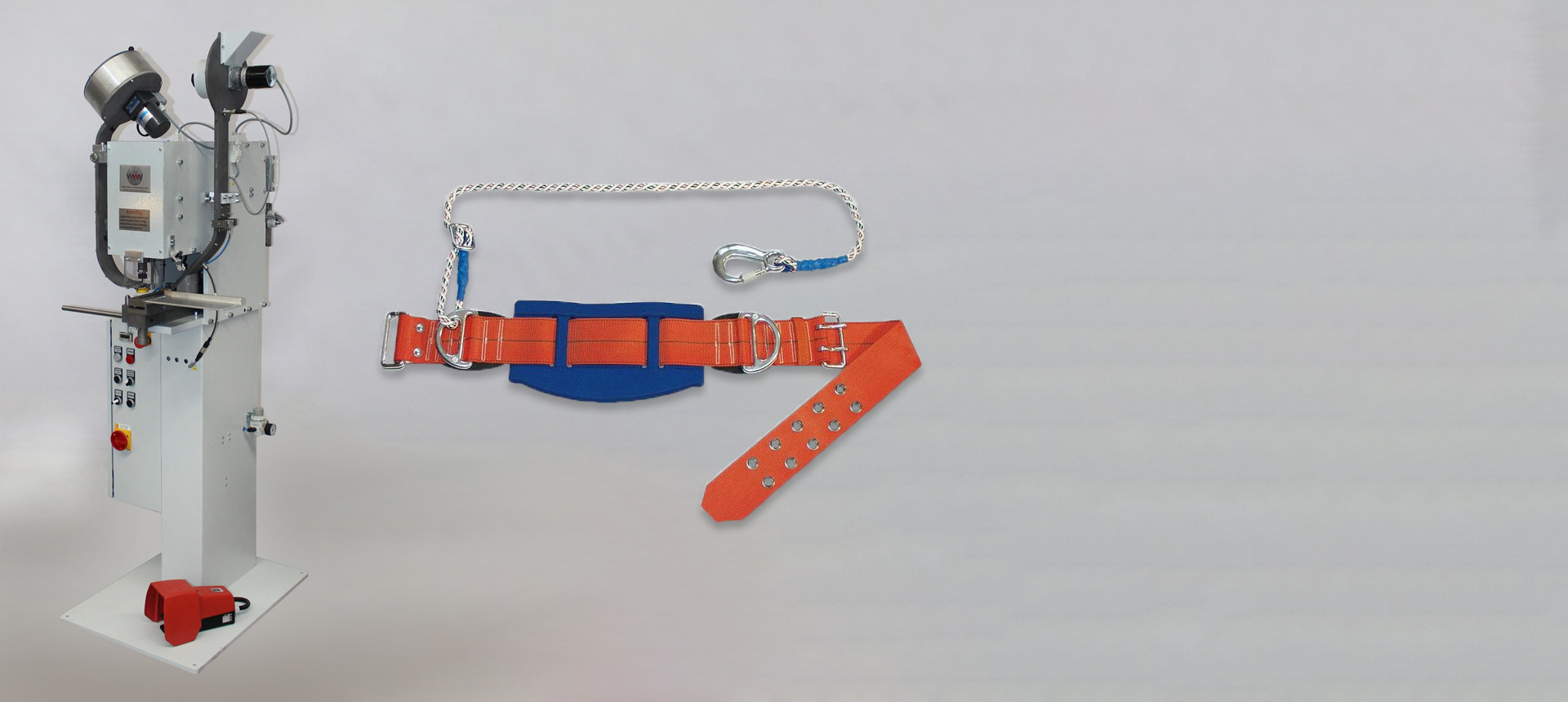

Eyelet machines

For professional eyelet processing, we offer a selection of robust and reliable machines, including hand eyelet machines, pneumatic eyelet machines, and electric eyelet machines in various designs.

Press

Rely on powerful solutions for processing eyelets, rivets, and other fasteners in a wide variety of materials. Our selection of hand and pneumatic presses offers you the ideal combination of control and performance.

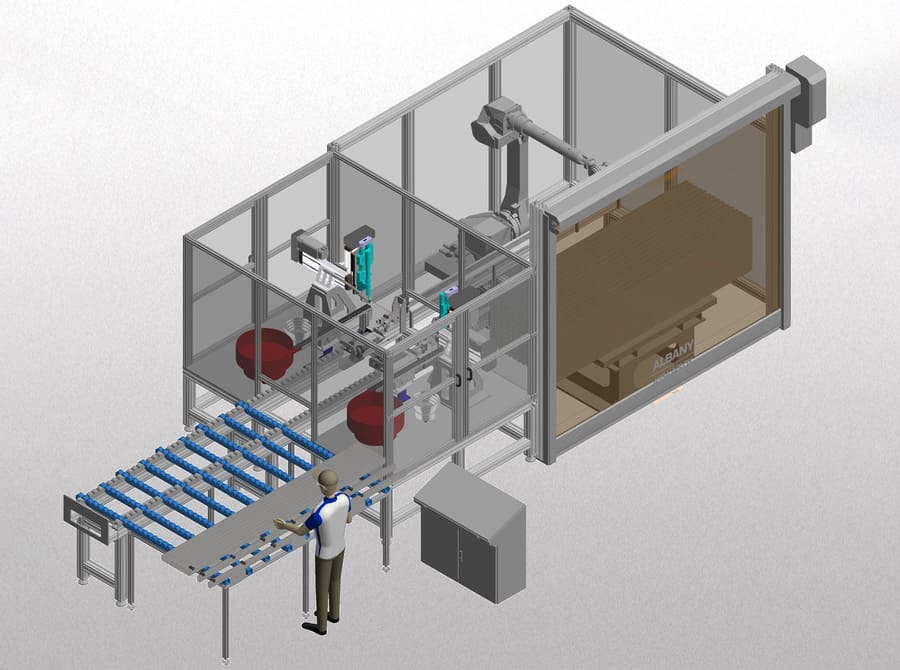

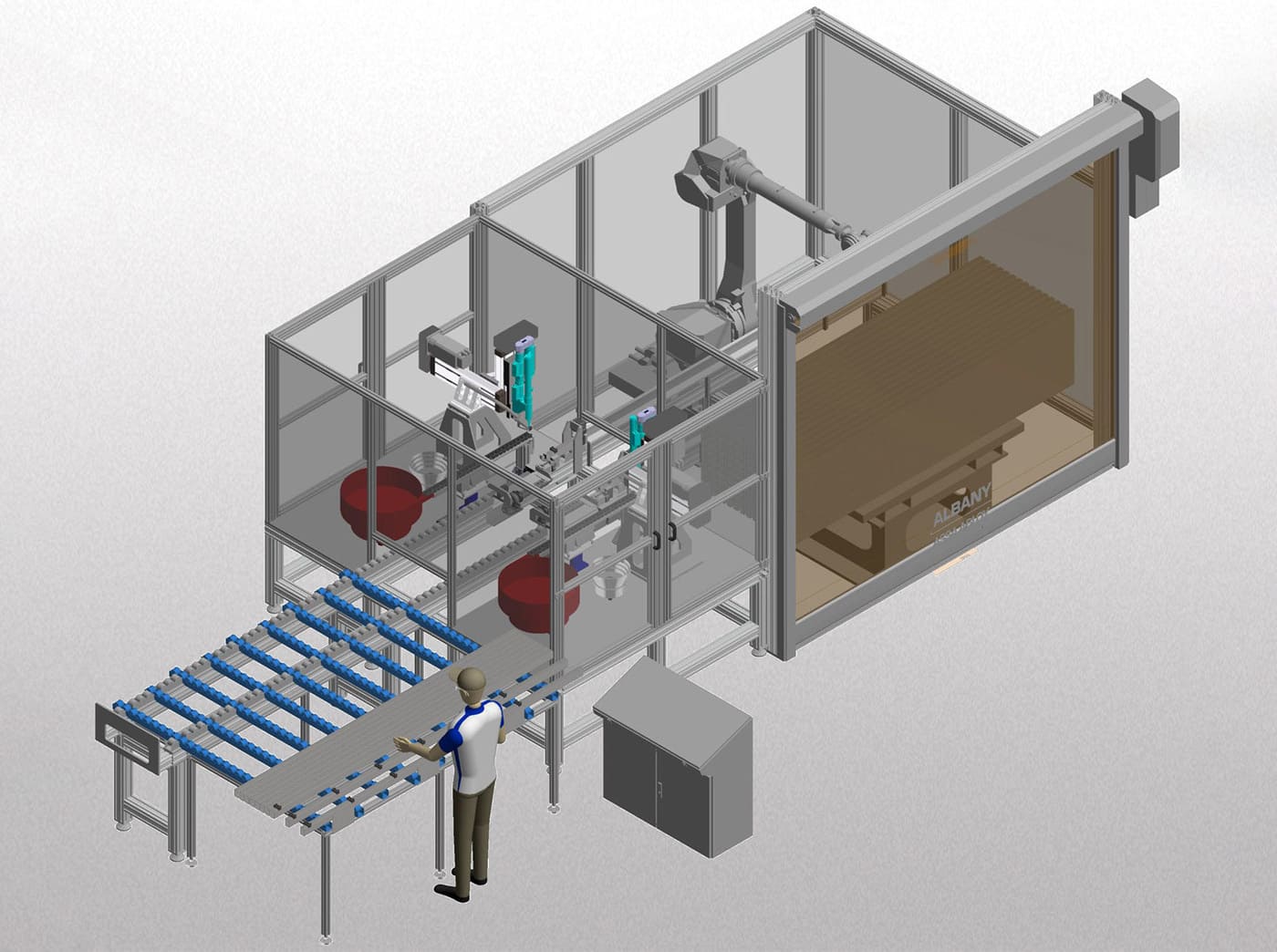

special machines

When standard solutions reach their limits, our highly specialized special-purpose machines offer the answer to your individual requirements in the processing of various applications.

Used machines

Are you looking for a cost-effective yet reliable machine for your joining needs? At Walter Winter Verbindungstechnik, carefully selected used machines are professionally reconditioned.

Service & Support

Downtime costs money – don’t waste any time! Do you need maintenance, repairs, spare parts, or overhauls? No problem – with us, you’re in the best hands…

…even for other brands!

Do you have any questions or are you looking for the perfect machine for your requirements?

Let's work together to create the perfect connection – we look forward to hearing from you!

Our services

At Walter Winter Verbindungstechnik, we offer you more than just high-quality products “Made in Germany.” From custom-made special machines that guarantee maximum reliability and efficiency, to a wide range of rivets and eyelets for a variety of applications, to our first-class customer service for maintenance, repairs, and spare parts—even for other manufacturers’ products.

custom-made products

With state-of-the-art technology and robust construction, our special-purpose machines guarantee maximum reliability and quality. This ensures a long service life and long-term efficient production – naturally made in Germany by Walter Winter Verbindungstechnik.

Maintenance, repair & spare parts – brand-independent

Is your production at a standstill or do you need preventive maintenance for your machines, even if they are from other manufacturers? Then Walter Winter Verbindungstechnik is the right place for you!

We understand how important a smooth production process is and offer you a comprehensive service for maintenance, repairs, fast procurement of spare parts, and professional overhauls—regardless of the manufacturer.

Rivets: The robust solution for permanent connections

When it comes to creating reliable and durable connections in your projects, rivets offer a proven and versatile solution. Established for centuries in craftsmanship and industrial applications, rivets enable a strong and durable connection between different materials.

From standard to special rivets – discover our wide range and find the right rivets for your applications. Our rivets can be used in the paper, cardboard, textile, plastic, and metal industries.

Eyelets: Reinforcement and functionality for a wide range of applications

Eyelets, typically round or oval metal rings, are extremely versatile elements with a wide range of applications. One of their main uses is to reinforce holes in materials such as paper, tarpaulins, leather, and textiles.

The integration of an eyelet prevents the material from fraying or tearing under stress, creating a robust passage for ropes, cords, and ribbons. Our range of eyelets offers the highest quality for a wide variety of applications—take a look at our selection.

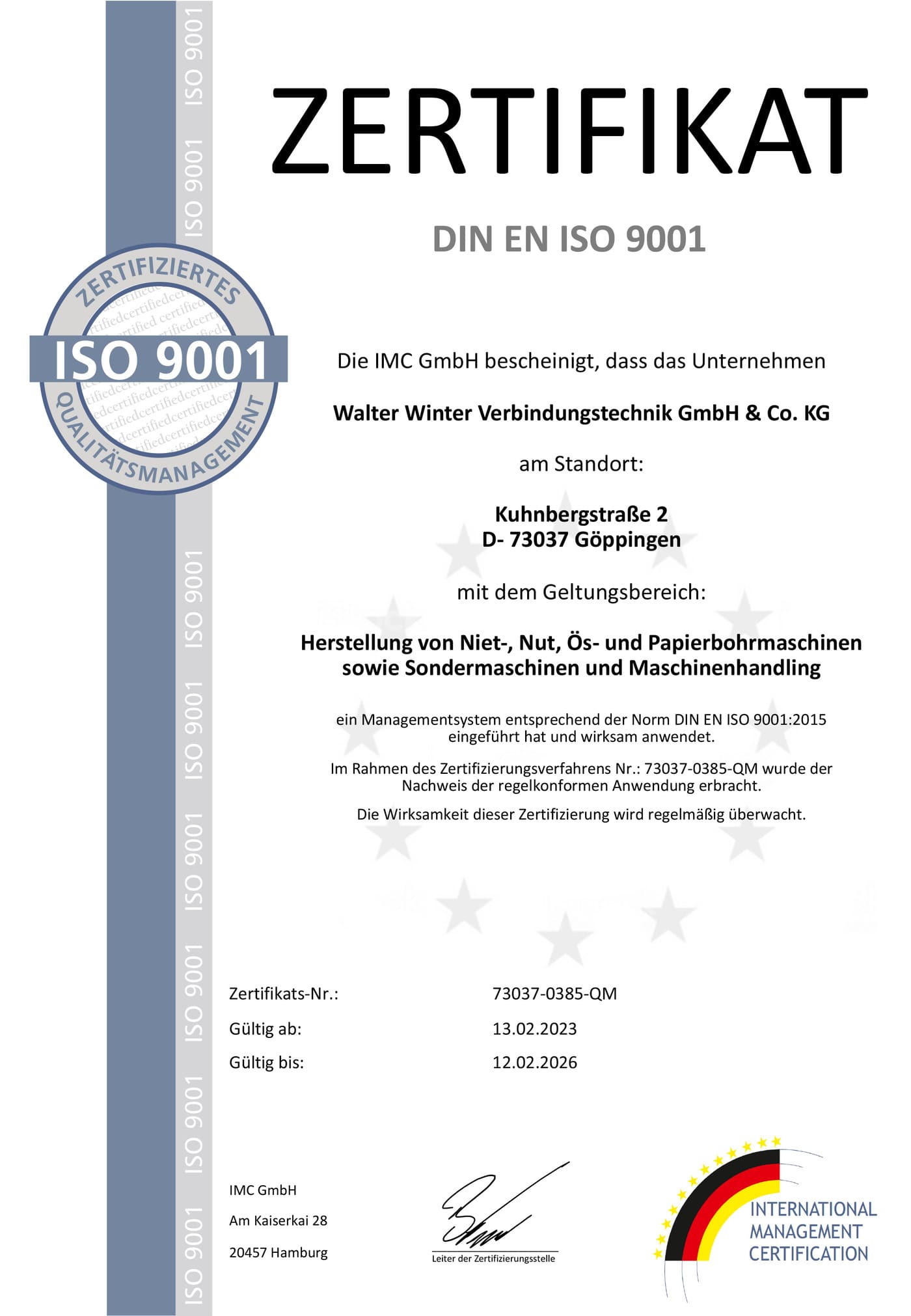

Certified quality management

Walter Winter Verbindungstechnik is certified according to DIN EN ISO 9001 and sets the highest standards for quality and precision. Through strict quality management, we ensure that our machines and products not only meet current standards, but also exceed our customers’ expectations. This is how we guarantee reliable and durable solutions for your joining technology.

Do you have any questions or are you looking for the perfect machine for your requirements? Let’s work together to find the ideal solution – we look forward to hearing from you!